Huangyutian Wang wins James Dyson Award 2021 - National Runner Up

15 September 2021

Our semester four Bachelor of Industrial Design student Huangyutian Wang made us proud on being in top three of the James Dyson Award 2021 with her innovative No Residue Bottle design. Her no residue bottle is meant to fix the issue of traditional pump-action bottles which are ineffective in getting all the remaining solution out of the container.

The James Dyson Award is an international design award open to current and former design engineering students with an aim to celebrate, encourage and inspire the next generation of design engineers.

Having competed with over 2,000 aspiring inventors from 28 countries and regions, Wang Huangyutian’s world-changing idea, and an environmentally friendly solution was inspired by how troublesome it is to get the last bit of shampoo or bodywash out of the bottle- where one has to turn the bottle upside down.

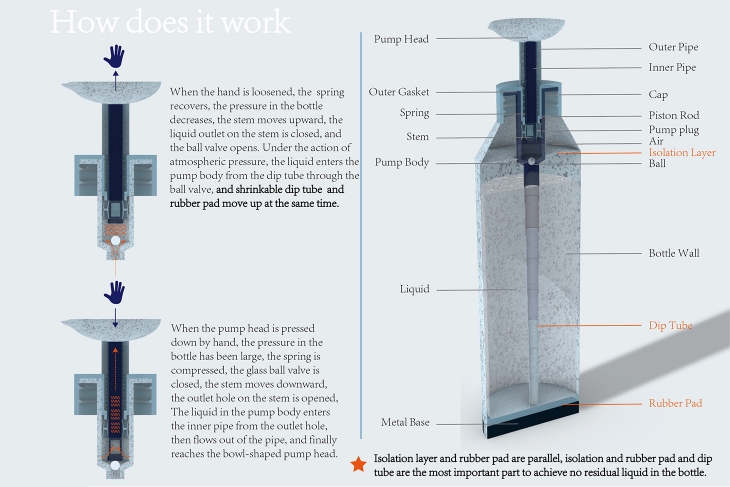

In explaining the design process of her design she said, “Through research, I found out that liquids like body wash and shampoo are too viscous. When only the last bit of liquid is left, the pump body cannot suck out the viscous liquid through the action of pressure, and the viscous liquid sticks to the wall of the bottle. This wastes part of the body wash and shampoo. One day it was raining, and I saw the wiper on the car window, I thought using something like a wiper to wipe off the viscous liquid on the wall of the bottle would be effective.”

“I then added the rubber pad to the bottle design and connected the rubber pad to the dip tube and let the dip tube become retractable. The dip tube and rubber pad can shrink with the amount of liquid in the bottle. This can solve the problem that the body wash cannot be pressed out when only a little bit is left at the bottom of the bottle. Lastly, I made a 3D model.”

The three components that makes Wang’s bottle unique are the retractable dip tube, a rubber pad at the bottom of the bottle and the bowl-shaped pump head at the top of the bottle.

Additionally, the whole bottle uses environmentally friendly material wheat fiber plastic. It is made of wheat straw and polymer resin compound, which can be degraded within 6-18 months under composting conditions.

In future Wang plans to perfect the structure of the bottle and hopes to partner with a manufacturer to promote her environmentally friendly residue-free bottle.

Wang is one of our many high-flying students across faculties who learn directly from industry experienced lecturers and provided with a platform to practice what they learn in the classroom in a real world setting through workshops, industry projects and competitions to prepare them for high income careers.